- VW is working on processes that will allow it to recycle battery materials multiple times, creating a closed loop.

- The automaker has teamed up with several partners, including chemical companies and universities, to research methods to create a largely automated dismantling process of used EV batteries down to the electrode or cell level.

- VW aims for this process to be decentralized and to consume less energy than creating new EV batteries from freshly mined raw materials.

While a number of automakers have launched programs aimed at EV battery recycling, a new program by Volkswagen along with several partners will attempt a far more complex task: Recycling EV batteries multiple times to create a closed loop when it comes to raw materials.

The effort will be an industry-first, aiming to increase sustainability in an era when battery materials are at a premium.

The project, dubbed HVBatCycle, seeks to keep the cathode materials, graphite, and electrolyte, in a closed material cycle permanently. Volkswagen, along with J. Schmalz GmbH, Viscom AG, and Taniobis GmbH, in addition to three universities, have launched a three-year effort to develop the needed technology to create such a process.

"The recycling of batteries and production rejects makes a decisive contribution to securing the supply of raw materials for our planned factories," said Sebastian Wolf, chief operating officer-battery cell at Volkswagen AG. "Through the HVBatCycle project, a holistic view of the recycling processes and thereby the implementation of the closed loop of battery materials is being prepared."

Volkswagen has already launched a pilot plant in Salzgitter, Germany, that recycles EV batteries, but even this process is limited. VW has the capacity to recycle only about 3600 battery systems a year at the facility, reusing over 90% of battery components. The effort to create a closed loop will be much more demanding, and aimed at lowering energy requirements compared to sourcing fresh raw materials.

The automaker says it needs to create a largely automated dismantling process of used EV batteries down to the electrode or cell level, including an almost loss-free separation of the active materials and carrier foils, in addition to the recovery of electrolyte and graphite.

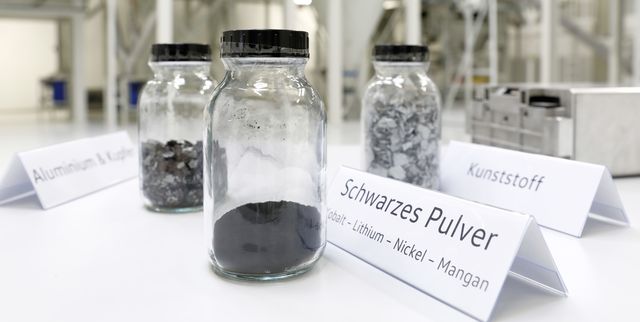

"In the following hydro-metallurgical processing of the 'black mass,' which consists of graphite and battery metals, using water and chemical solvents, the focus is on early and selective extraction of the lithium in soluble form as well as leaching, precipitation and refining of contained metals as a mixed hydroxide concentrate," the automaker points out.

It is in this stage of the process that VW plans to find out whether separating the metal compounds is actually necessary to produce new cathode material. VW aims to show that graphite and important electrolyte components can indeed be used again in battery-suitable standard.

The automaker also wants to explore if such a closed loop can be decentralized as much as possible in Europe, in order to save energy. Therefore, one single site in Europe for this type of battery EV recycling is not ideal, given just how many EVs there will be on the roads of over two dozen countries.

"This favors a local circular economy and secures strategically important raw materials, which significantly reduces Europe’s dependence on other regions of the world," the automaker adds.

Clearly, there are many technological challenges ahead as VW and its partners work on this project. But this issue is expected to become much more acute in the coming years as older EVs start to retire en masse. A vital step in the process is the logistics of collecting these retiring EVs to obtain the battery materials and perhaps recycle other vehicle components, so the materials loop can begin again. At that point would VW (and perhaps other automakers) be purchasing back these aged vehicles? If so, the final owner of the vehicle could extract a decent payout, even if it's only a down payment on a new EV. If, on the other hand, VW's plan would require vehicle owners to pay to recycle their vehicles, consumer buy-in will be in question.